RANGE OF EMULSIFIERS

Our high-quality emulsifiers are designed to meet a variety of needs.

Reactivity

Limit

Industrial activities use and store many flammable liquids. Class B fires involving these products are fought by in-house teams and by fire-fighters using foam.

You need personalized support

Our teams are at your disposal to answer any questions you may have.

What is an emulsifier?

An emulsifier is an aqueous solution which reduces the surface tension of water, thus promoting foam formation. Each emulsifier can be classified according to its physico-chemical nature, the type of solvent on which it is effective and the expansion ratio selected for its use.

We distinguish between synthetic-based emulsifiers, with a foaming base made up of hydrocarbon surfactants comparable to the active ingredients found in liquid soaps and detergents; and protein-based emulsifiers based on hydrolysates of proteins, generally animal proteins (horns, hooves, blood, etc.). In Europe, synthetic-based emulsifiers are the most popular.

How to choose the right emulsifier?

Certain criteria must be respected when choosing an emulsifier, so as not to compromise the safety of people and property.

First of all, the selection of an emulsifier will be directly correlated to the nature of the risk, and therefore to the solvent on which it is to be used (water-miscible or not).

Isolates flammable liquid from the air

Class B fires

Synthetic or protein emulsifiers

They can be used on apolar solvent fires (hydrocarbon type):

- Synthetic emulsifiers (S): their extinguishing performance and resistance to reignition are very limited.

- Fluoroprotein (FP) emulsifiers: obtained by adding a fluorinated telomer.

- Film-forming AFFF emulsifiers (synthetic-based floating film-forming agent and FFFP: fluoroprotein floating film): these are obtained by adding film-forming fluorosurfactant(s) to synthetic or protein foaming bases. The floating film thus isolates the flammable liquid from the air and spreads rapidly, enabling extinguishing. They are particularly suitable for slick fires.

- Fluorine-free emulsifiers (F3): these are synthetic emulsifiers designed for applications similar to AFFF and FFFP.

Alcohol-resistant (AR) synthetic or protein emulsifiers

They can be used on polar solvents (i.e. water-miscible solvents such as alcohols, acetones, aldehydes, esters, amines, etc.):

- S-AR, FP-AR, fluorine-free AR, AFFF-AR or FFFP-AR emulsifiers contain fluorinated or non-fluorinated polymers which form a "gel-like" film on the surface of the polar liquid.

They are also known as multipurpose foamers, but are often less effective on hydrocarbon fires.

The case of fluorinated AFFF emulsifiers

In view of their toxicity, certain fluorinated emulsifiers are gradually being banned. These include emulsifiers containing PFOS (perfluoro octanoic sulfonate) and emulsifiers containing PFOA (perfluoro octanoic acid) and related substances.

The PFAS family to be totally banned by 2025

How does an emulsifier work?

How do you produce fire-fighting foam?

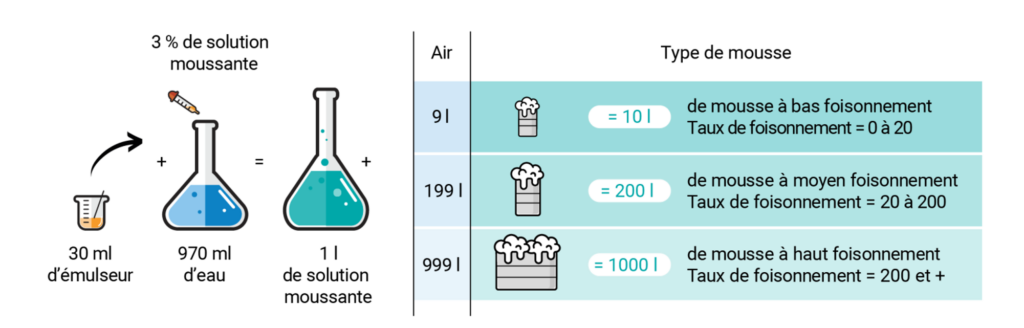

When mixed with water in the right proportions, the foaming agent forms a foaming solution. Heterogeneous mixing of this solution with air produces a physical foam, specially recommended for extinguishing Class B fires.

How to calculate the quantity of emulsifier?

Water and emulsifier must be mixed in the right proportions to guarantee maximum efficiency; the nominal concentration must therefore be respected. This dosage is communicated with the products. For example, a rate of 3% means that 3 portions of emulsifier are added to 97 portions of water to obtain a 100 portion foaming solution.

This ratio depends on the type of emulsifier or fuel. When an emulsifier is described as 1 x 3, this means that the ratio of concentration to water must be 1% on hydrocarbon fires and 3% on polar solvent fires.

The different types of expansion

Fire-fighting foam is formed by adding air to the foam generator. The ratio between the volume of foam obtained and the volume of foam-forming agent used to produce it is known as the Foisonnement.

Low Foisonnement

Generally used on large hydrocarbon fires (storage tanks, retention basins). Its higher density enables long-range spraying with lances or cannons. Low-foaming foam is not sensitive to atmospheric conditions such as wind or rain: it is stable and provides resistant coverage. Its high water content also ensures significant cooling.

Medium Foisonnement

Used for smaller surfaces (solvent rooms, cellars), usually in enclosed or partially enclosed areas where side walls limit spreading. The foam in Medium

can be projected up to ten meters. Its low density makes it sensitive to wind and weather.

High Foisonnement

Used for smaller surfaces (solvent rooms, cellars), usually in enclosed or partially enclosed areas where side walls limit spreading. The foam in Medium

can be projected up to ten meters. Its low density makes it sensitive to wind and weather.

How does fire-fighting foam affect a fire?

An emulsifier acts on a fire by suppressing the oxygen supply. They are composed of surfactants that activate the wetting and foaming action.

The wetting action reduces the surface tension of the water, allowing it to spread more rapidly over the fuel surface and penetrate solids faster than water alone.

The foaming action adds air to the solution, which forms a foam that generates numerous bubbles to create a stable mat. The foam spreads quickly and evenly over the surface of the fuel and remains stable for a long time.

The foam mat separates the fuel from the flammable vapors in the air, stopping the supply of oxygen and preventing reignition.